Table of Contents

Founded in 2012, Dhruva Space is a full-stack space engineering solution company based in Hyderabad, India, and has a growing European presence in Graz, Austria.

From satellite platforms to separation systems, as well as ground infrastructure and mission operations, Dhruva is one of the few, and the only Indian based full-stack space company. Since its founding, the company has operated eight satellites across four launches.

The most recent mission from Dhruva was for the company’s “Launching Expeditions for Aspiring Payloads” or LEAP program. Following a successful test demonstration during LEAP-TD, the company embarked on a critical mission this August: launching its first two customer payloads to orbit via a Falcon 9 rocket.

With the success of Leap-1 in their rear view mirrors and in a nation rapidly defining its role in the global space economy, Dhruva Space represents more than a company; it is a crucial piece of the next chapter of Indian space exploration.

Charting India’s Role in the Global Space Economy and Dhruva's Vision for Space Access

As Dhruva Space is growing both technically and internationally, we were interested in learning more about the company’s underlying goals and how it sees India’s changing place in the global space economy.

In this interview with the team at Dhruva, we asked a handful of questions, from engineering philosophy to the future of the Indian space industry. Let's dive in!

What excites you most about the “final frontier”?

Sanjay Nekkanti, CEO & Co-founder, Dhruva Space: For Dhruva Space, Space is about exploration and building infrastructure that supports various impact areas such as climate monitoring, secure communications, global connectivity, disaster management, and scientific discovery. Our work spans satellite platforms, subsystems, ground systems, and mission services. Every element contributes to making access to space more routine and highlights the tremendous impact of space tech. So, the excitement comes from enabling others — whether it’s a research institute validating critical research, a Defense agency strengthening our borders, or an Enterprise scaling a new innovation. Every satellite we build, every payload we integrate, and every ground station we establish, adds a new capability, expanding the ecosystem and lowering the barrier for those sectors that have not yet gone to Space or leveraged Space-based data.

That sense of compounding impact motivates us.

How does Dhruva differentiate itself from others in India and globally?

Sanjay Nekkanti, Chief Executive Officer & Co-founder, Dhruva Space: One of the biggest challenges in the current Space ecosystem is complexity and fragmentation in realizing a Space mission. It is a complex, costly, and time-intensive process experience by customers to secure a satellite bus with subsystems, launch facilitation, integration services, and ground infrastructure.

Dhruva Space’s USP solves that customer pain point. We are one of the few companies globally, and the only one in India, offering end-to-end mission delivery under one roof. From satellite platforms and subsystems to launch facilitation and separation systems, as well as ground infrastructure and mission operations, we provide either an integrated solution or individual offerings depending on the requirement. Customers don’t have to manage multiple contracts; they can work with one partner who takes responsibility from design through launch and operations. This approach makes lead times for missions faster, more reliable, and more scalable. Globally, this positions us uniquely: we bring the agility of NewSpace companies, but with the systems discipline and reliability that Governments and Tier-1 OEMs expect.

What is Dhruva’s vision for India’s role in the global Space economy over the next 10-20 years, and how does Dhruva itself seek to contribute?

Chaitanya Dora Surapureddy, Chief Financial Officer & Co-founder: I think the future is very bright. The Decadal Vision released by India’s Space Regulatory body, IN-SPACe, envisions that satellite manufacturing shall comprise over 10% of the US$44 billion Indian space economy’s share in the global markets. With the country’s continued emphasis on expanding the space economy by five times in the next decade, Dhruva Space is well-positioned to capitalize on the dynamic Indian and global markets, driving innovation and delivering impactful solutions. It is clear that, to the Government and private sector alike, Space is a sector integral to nation-building.

Dhruva Space’s mission is to help India get there. Today, we are industrializing satellite platforms, subsystems, and ground services so that customers can access Space faster, more reliably, and on a cost-effective basis. Tomorrow, these same capabilities will evolve into the building blocks of interplanetary infrastructure, including modular satellites, scalable operations, and ground systems that extend from Earth to the Moon and beyond. Our vision is that when humanity looks back twenty years from now, whether at constellations circling Earth or the first steps on Mars, Indian infrastructure will have been part of the backbone that made it possible.

We also see Dhruva Space as an enabler for industries that have yet to tap into Space or leverage Space-based data in their operations, for example, fisheries & aquaculture, forestry & wildlife management, banking & finance.

What were the biggest hurdles on your path to orbit?

Abhay Egoor, Chief Technology Officer & Co-founder, Dhruva Space: Getting to orbit has been as much about solving systemic challenges as it has been about advancing technology. In our early years, the lack of accessible testing infrastructure was a significant hurdle. For the first three to four years, we had no launches and instead were focused on building foundational technologies. When the time came to test and qualify them, access to facilities was limited. We addressed this through a hybrid approach, working with both ISRO and private facilities, and were among the first private companies to sign formal agreements with IN-SPACe and ISRO. Even today, while Dhruva Space continues to invest in establishing our own facilities, infrastructure access remains an industry-wide bottleneck.

Regulatory processes also required perseverance. Securing authorizations for spectrum, RF systems, and launch clearances often involved long timelines. However, because Dhruva Space was maturing alongside India’s evolving Space policy ecosystem, we built compliance into our mission design from the outset. Today, we have one of the strongest in-house Regulatory teams in India, and that capability has become a core part of our resilience.

Additionally, a decade ago, it was rare to find engineers with direct experience in building and testing Space systems. We invested heavily in building talent pipelines, pairing talent with experienced professionals, and today our 200+-member team has become one of the most capable satellite engineering cohorts in India. For me, each of these hurdles was an opportunity to pivot and has enabled us to become more resourceful, making Dhruva stronger and more competitive.

From Vision to Engineering Reality

Now that we have a more comprehensive understanding of the space business and Dhruva's fast expanding mission, let's look at the engineering philosophy that enable it all.

Dhruva has emphasized building an end-to-end Space infrastructure. From an engineering standpoint, how do you balance modularity and standardization with the need to tailor systems for specific customer missions?

Abhay Egoor: At Dhruva Space, our philosophy has always been to design satellite platforms that are application-agnostic. This means they can host a wide variety of payloads across use cases such as Earth Observation, RF communications, technology demonstrations, or multiple payloads combined, without requiring a redesign each time.

To make this possible, we have invested in developing three core classes of satellites. Each platform is sized and engineered to suit a particular spectrum of missions, whether that means a compact satellite for universities and technology demos, a nanosatellite capable of Earth Observation and RF applications, or a larger microsatellite able to host complex payloads that require fine point accuracy and higher power budgets. By doing so, we avoid reinventing the wheel for every mission and instead start from a standardized, flight-proven platform.

Standardization, however, is only part of the solution. We combine it with modularity at the subsystem level, so every satellite is inherently customizable. For instance, one mission may demand a high-data-rate transmitter capable of handling 500 Mbps, while another may only need a transmitter operating at 50 Mbps. Rather than redesigning an entire spacecraft, we simply swap subsystems to deliver the most optimized and cost-effective configuration. It’s similar to how the automobile industry operates: a hatchback, sedan, and SUV each provide a familiar platform, but customers can choose variants based on their needs without altering the core design.

This balance of standardization and modularity allows us to offer missions that are scalable, adaptable, and fast to deploy. Customers benefit from faster timelines, reduced cost, and proven reliability, while still receiving satellites tailored to their specific requirements.

Following the successful deployment of LEAP-1, what is next for Dhruva, and what did you learn from previous missions that influenced it?

Sanjay Nekkanti: LEAP-1 is an essential milestone as Dhruva Space’s first commercial mission, with more companies leveraging our LEAP initiative in the coming years. Tier 1 global OEMs such as Sodern, ArianeGroup, and emerging startups are lined up for future LEAP missions.

Of course, to realize these many missions in these on-demand TATs, we have noted the need for the necessary infrastructure. That said, construction is underway for Dhruva Space’s 280,000-square-foot facility in Hyderabad, with the first phase being operational in early 2026. This site will allow us to scale production of satellites in the 300–500 kg class while supporting a broader portfolio of mission-critical subsystems, including Space-grade Solar Panels. The facility is designed not just for scale, but also for speed and repeatability, bringing Space manufacturing practices closer to industrial production standards.

We are also actively doubling down on our Ground segment capabilities. As the first Indian company to be authorized by the GOI to provide GSaaS, we are expanding our sovereign ground station network and advancing our proprietary mission operations software, Integrated Space Operations & Command Suite (ISOCS), which will enable customers to truly own, track, and command their Space assets in orbit.

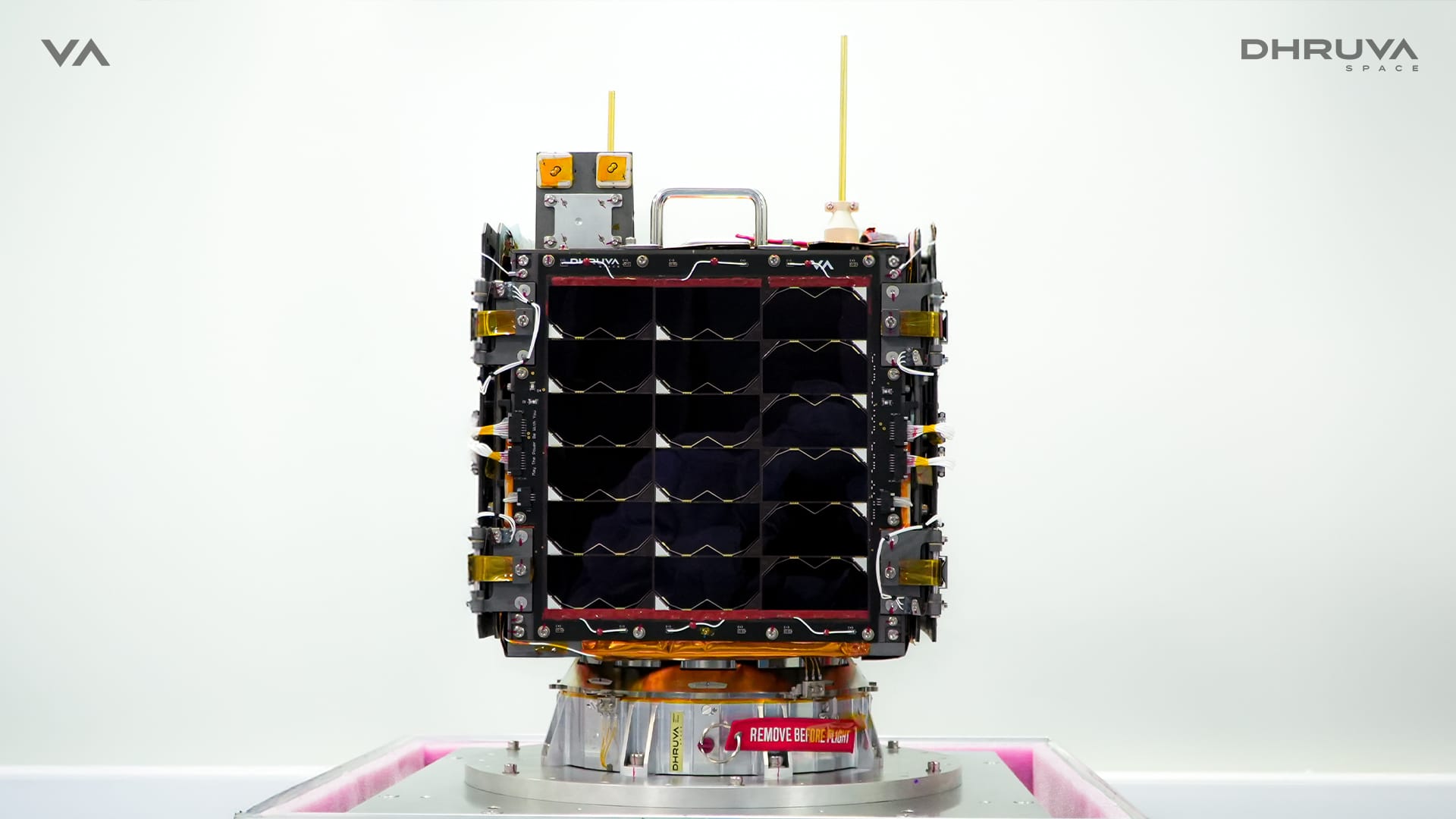

Abhay Egoor: LEAP-1 marked a significant milestone for Dhruva as our first complete standalone commercial mission using the P-30 satellite platform. Nearly all subsystems were indigenized in-house, from the ADCS and solar panels to onboard computers and communications chains. The mission was as much a validation of our engineering as it was a demonstration of our operational maturity.

The lessons we carried into LEAP-1 came directly from earlier missions. Ground testing had to be exhaustive, because designs that worked in the lab could still fail under the stresses of launch. As a result, we developed highly detailed test plans to validate every function before flight. We also recognized the importance of operational readiness. LEAP-1 was a mission where we operated end-to-end, in terms of mission planning, ground station communications, and the satellite’s in-orbit modes. That experience expanded our role from manufacturer to full mission partner.

Most importantly, LEAP-1 confirmed the value of our modular design philosophy. Because subsystems were swappable and integration-friendly, assembly was streamlined and scalable. And because the platform was designed to accept customer payloads without modification, we were able to integrate a third-party payload seamlessly in terms of structure, electrical connections, and thermal compatibility. That ability to take responsibility for the entire mission validated Dhruva’s model and set the tone for future missions.

Additive manufacturing, composites, and sustainability are transforming spacecraft production. Which advanced manufacturing techniques is Dhruva integrating into your supply chain, and how are you designing for responsible de-orbiting or on-orbit servicing?

Abhay Egoor: We see additive manufacturing as a powerful tool, but we are deliberate in how we use it. While we do not yet rely heavily on metal additive manufacturing for Spacecraft, we are actively exploring multi-material approaches where a single component can be fabricated with different materials in one build. For instance, a polymer structure with embedded metal inserts can be manufactured as a single part, eliminating joints, reducing weight, and improving reliability.

We also make extensive use of carbon-fiber composites. Their strength-to-weight ratio makes them ideal for reducing mass while maintaining structural integrity. Our engineers have developed innovative ways to apply them to optimize subsystems where every gram counts.

Regardless of the method, every part undergoes rigorous validation. Additive and composite components are subjected to the same environmental, thermal, and mechanical testing as traditional parts. There are no shortcuts. In Space, every piece of hardware must be proven flight-ready. For us, advanced manufacturing is about enabling smarter, lighter, and more reliable designs that ultimately expand the capability of our satellites without compromising dependability.

Abhay Egoor: Sustainability is not an afterthought for us, but is embedded in how we design satellites. Even though there is not yet a strict mandate in India for de-orbiting, Dhruva Space has made a conscious decision that all satellites above a specific mass class will be equipped with propulsion systems. This capability serves two vital purposes. First, it enables collision avoidance, allowing satellites to maneuver away from potential conjunctions and reduce the risk of in-orbit collisions. Second, it ensures responsible end-of-life management. By dedicating propellant mass specifically for de-orbiting, we guarantee that our satellites re-enter the atmosphere and burn up, rather than lingering as Space debris.

We are also closely tracking advancements in on-orbit servicing and debris removal, and we design our platforms with the flexibility to integrate with these frameworks as they mature. The principle is simple – every satellite we put up should also have a clear and responsible plan for how it comes down. That way, our customers benefit from reliable missions, and the industry as a whole benefits from cleaner, safer orbits.

Ground Stations are often the unsung heroes of Space missions. How are you approaching RF challenges like interference, bandwidth demand, and antenna design?

Abhay Egoor: Ground stations are critical — a mission is only as good as the data you can get back. Dhruva today has access to 13 ground stations across 10 countries, through its own infrastructure in Hyderabad and partnerships with companies like Infostellar and SSC. This global footprint provides redundancy during critical phases like the Launch Early Orbit Phase (LEOP), resilience against local interference, and broader coverage for data-intensive missions.

From an engineering standpoint, we address challenges on both the Avionics and Software sides. High-gain dual-band antennas provide reliable links for both telemetry and high-speed downlink, while adaptive filtering and software-defined radios let us optimize signals in real time. The aim is straightforward: to make the ground segment as scalable, resilient, and dependable as the satellites it supports.

And lastly, if you had unlimited resources to send a spacecraft anywhere in our solar system, where would you send it? Why?

Abhay Egoor: If resources were unlimited, I would look beyond our solar system. We already know a great deal about our immediate planetary neighbors, but what fascinates me most is the unknown that lies outside.

For me, exploration has never been only about finding answers; it has always been about asking bigger, better questions. The James Webb Space Telescope has shown us breathtaking glimpses of galaxies, star systems, and cosmic phenomena we barely understand. Those images are humbling and exhilarating at the same time. They remind us of how small we are, and how much remains to be discovered.

The Future Looks Bright

As India continues to push the envelope in the rapidly growing and evolving space industry, Dhruva Space is setting itself up to be a key player, both for India and nations abroad. The vision Dhruva has for the future is nothing short of awe inspiring. Like many others who look to the stars, Dhruva seeks to open the doors to space and to peer into our cosmos like never before.

Its massive facility that is under construction in Hyderabad and a growing international presence signals what is to come: more missions, more innovation and a new area of space accessibility.

As India begins its trek towards the stars, Dhruva Space stands at the heart of this movement—quietly building the infrastructure on Earth and in-space, that will make such endeavors possible.

Closing Remarks

A special thanks to Siddharth Varanasi for his communication and to Vikranth for helping us land the interview!

If you would like to stay up to date on Dhruva Space and their missions, give them a follow on their social medias, or head to their website, here!