Table of Contents

Last year at the American Institute of Aeronautics and Astronautics (AIAA) technical symposium, Agile Space Industries, a Colorado-based startup, introduced a groundbreaking rocket engine currently in development. This innovative propulsion system aims to bridge the gap between two primary forms of in-space propulsion: chemical propulsion, known for its high thrust but lower efficiency, and electric propulsion, which offers higher efficiency but lower thrust.

The Problem With In-Space Propulsion

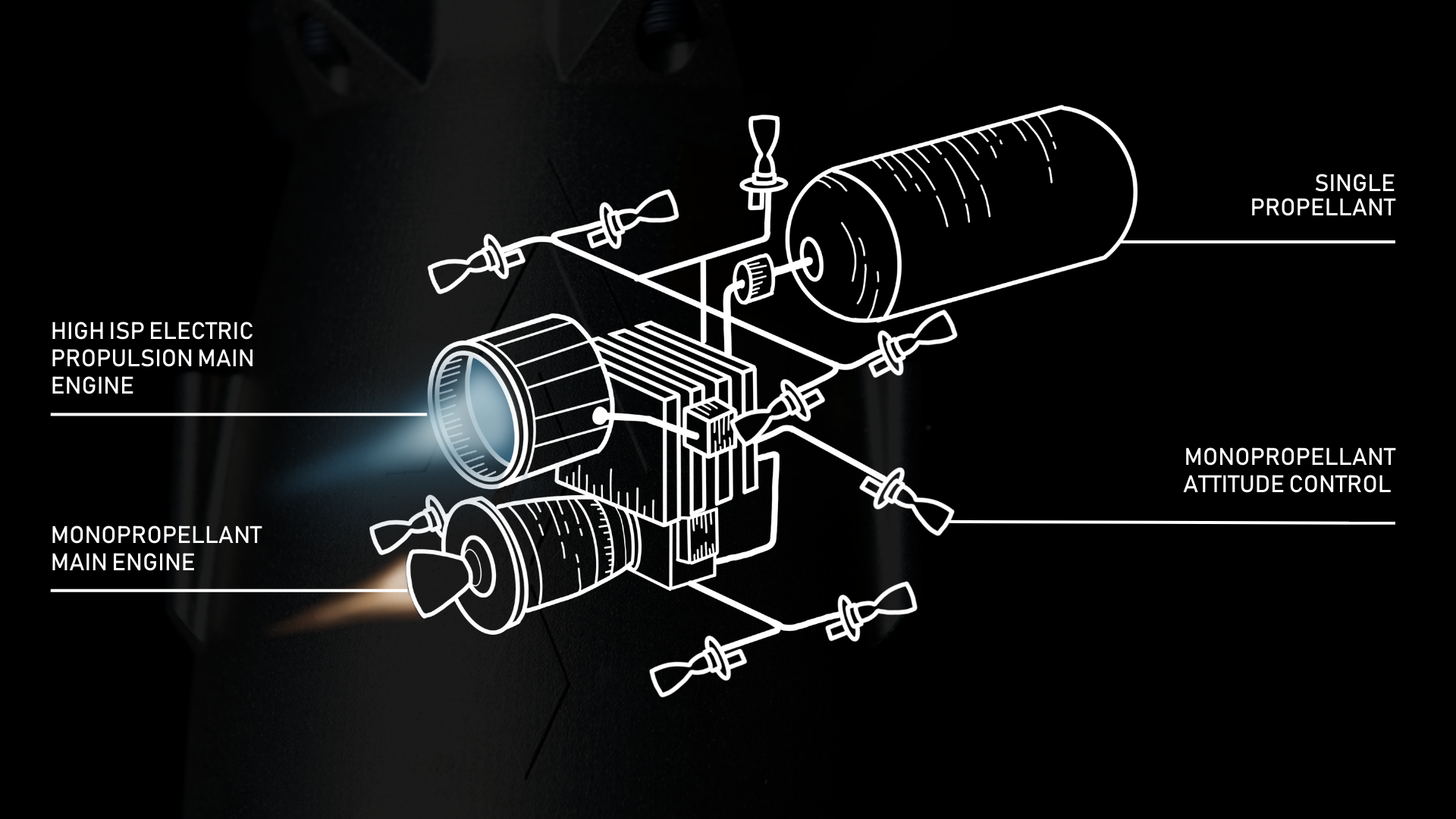

Selecting the right propulsion system can be challenging, as many missions require high thrust and high efficiency at different stages. It is so crucial that some mission objectives cannot be met at all, as you have to settle for one or the other. For instance, electric propulsion is king if you have a long-duration burn. However, chemical propulsion is superior when a rapid change is needed to avoid debris or a significant burn is required for orbital insertion. That is why Agile Space seeks to overcome this dilemma by developing a chemical-electric, dual-mode rocket engine that utilizes hydrazine as its propellant. This engine will also feature Reaction Control Thrusters (RCS), creating a versatile three-in-one propulsion system that is ideal for a wide range of spacecraft missions.

Breakthroughs in Ion Propulsion

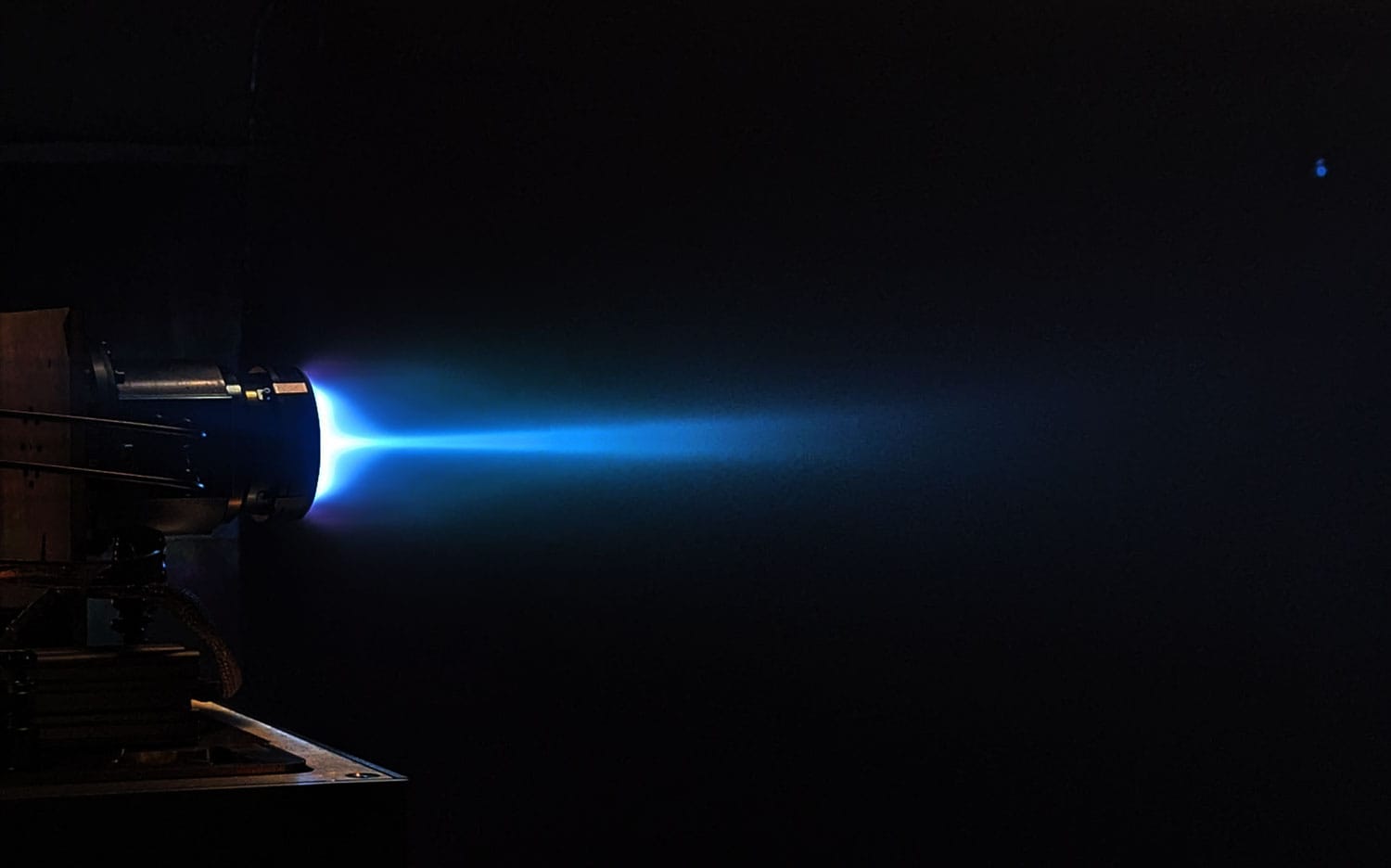

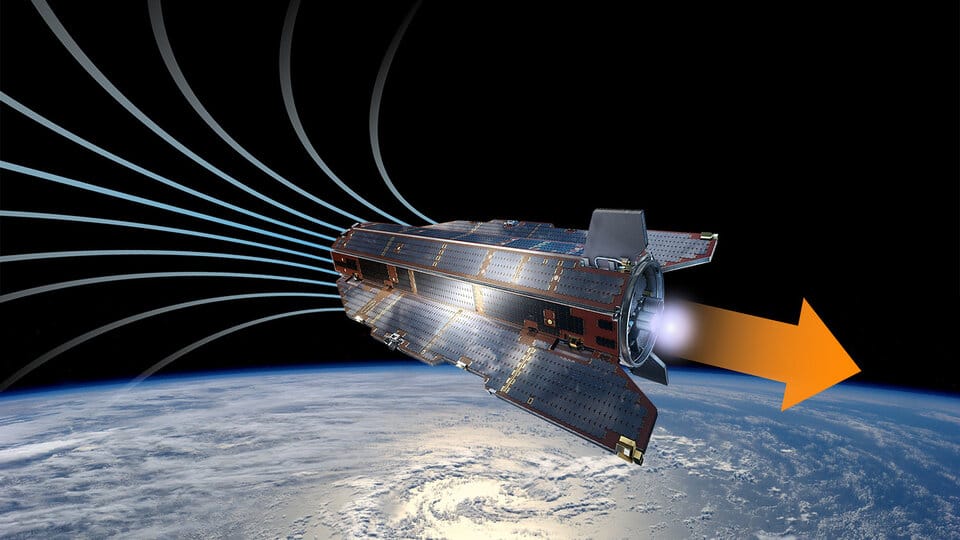

Since NASA’s SERT-1 spacecraft successfully tested the first electric engine in 1964, engineers have made significant advances in ion propulsion technologies. Traditionally, ion engines have relied on rare and expensive noble gases, such as Astra's Spacecraft Engine which uses xenon and krypton. However, recent innovations have explored more common gases, such as argon. One of the most fascinating developments in the industry is that of “air-breathing electric propulsion” (ABEP). This approach involves a spacecraft collecting air molecules, particularly nitrogen, in the upper parts of the atmosphere while in a very low Earth orbit.

Organizations like the European Space Agency (ESA) and NewOrbit Space are actively researching ABEP systems. In 2017, ESA, in collaboration with Italian company SITAEL, conducted the first successful laboratory tests of such systems. Meanwhile, NewOrbit Space achieved positive results from vacuum chamber tests, reporting an impressive specific impulse (ISP) of 6,380 for its engine—substantially higher than that of the renowned RL-10 hydrolox rocket engine, which has an ISP of 465. By utilizing the abundant nitrogen in Earth’s atmosphere, ion propulsion systems could become significantly more cost-effective and capable.

Why Noble Gasses Reign Supreme for Ion Propulsion

Despite the promise of air-breathing propulsion systems, there are some notable challenges. Most ion engines traditionally utilize noble gases due to their stability and low reactivity. In contrast, air-breathing systems would use trace amounts of nitrogen and oxygen found in the upper atmosphere. Oxygen’s reactivity poses a risk of engine damage over time, which is exacerbated by the fact that ion engines operate continuously at low thrust. While nitrogen is also somewhat damaging, further research is needed to understand its long-term effects on engine performance.

Comparing Chemical and Electric Propulsion Systems

While ion engines boast remarkable efficiency, up to four times greater than chemical rockets, they produce significantly lower thrust. For instance, Aerojet Rocketdyne’s Advanced Electric Propulsion System (AEPS) generates approximately 1.7 newtons of thrust and has an ISP of around 2,300. In contrast, the RL-10, as mentioned earlier, is one of the most efficient chemical rocket engines ever built, producing a staggering 106 kilonewtons, equivalent to 60,000 times the thrust of the AEPS, with an ISP of approximately 450.

This fundamental disparity highlights the core issue in selecting propulsion systems: striking a balance between low thrust efficiency and high thrust power. But what if you could have both with little sacrifice?

The Advantages of a Dual-Mode System

That is where Dual-mode electric propulsion comes in. The benefits of having a single power pack have been a topic of discussion among space agencies and universities for some time. Achieving high efficiency and high thrust with a single power pack offers immense potential for more flexible and varied missions, minimizing the need for design modifications. However, the challenge lies in identifying a suitable fuel for both chemical and electric propulsion.

Agile Space Industries, the United States’ leader in hydrazine propulsion, aims to capitalize on this need by leveraging their expertise on the propellant. The byproduct of hydrazine is primarily nitrogen, accounting for approximately 78% by weight, and hydrogen. This combination reduces corrosive wear on the system compared to the aforementioned air-breathing systems that rely on more reactive gases. Furthermore, hydrazine’s reactivity as a chemical propellant makes it an excellent choice for high-thrust applications, while also being simpler in design than other chemical systems, such as those that use cryogenic propellants.

While little is known about this new engine, we should expect to hear more from Agile about its development in the coming months! Blue Origin’s “Blue Ring” system is also set to use a duel-mode propulsion system powered by hydrazine and xenon.

We’re rapidly assembling Blue Ring's advanced hybrid solar electric propulsion-chemical, or SEP-Chem, system. The aft module stores hydrazine and xenon, while the forward module stores nitrogen tetroxide and helium. Congrats to the Blue Ring team on this critical step to first… https://t.co/UWlQE1gD5B

— Dave Limp (@davill) August 13, 2025

About Agile Space Industries

Founded in 2009 under the moniker "Advanced Mobile Propulsion Test" and later incorporated into Agile Space Industries in 2019, Agile is an in-space propulsion company based in Colorado, developing a wide variety of hydrazine thrusters for various applications. Throughout their years, the company has created a wide variety of engines, from the small A110 (111N of thrust) to the giant A2200 (2220N).

The company has also been selected to provide Astrobotic with engines for their upcoming Griffith lander.

With its dual-mode rocket engine, Agile Space Industries is poised to revolutionize in-space propulsion, offering a solution that combines the strengths of both chemical and electric systems. As the aerospace industry continues to evolve, innovations like these will pave the way for more ambitious missions and the exploration of new frontiers.